- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Careers

- Suppliers

- Contact Us

- IFI Connection

- Search

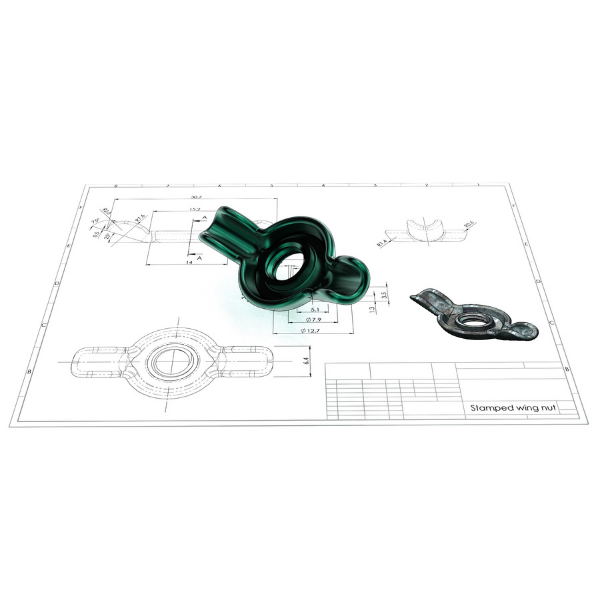

Stamping is the manufacturing process by which a metal sheet is pressed to form a specific shape. Raw pieces of sheet metal are pushed through a stamping press and altered by the die to produce high volume of identical components. There are a wide variety of fasteners that are made by stamping. These include nuts, bolts, washers, rings, clamps, and others.

Field is the #1 choice for all your metal stamping needs. Currently, we source more than 120,000 unique SKUs for more than 175 vendor managed inventory (VMI) programs in more than two dozen countries. We do this while setting the standard in the industry maintaining 99.96% order shipped correctly and 99.8% on-time delivery average ratings for our customers.